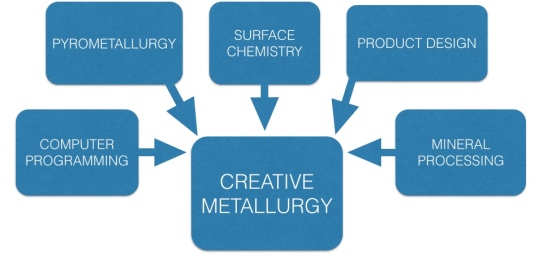

The discipline of Creative Metallurgy involves in depth understanding of several technical areas as well as an understanding of basic aesthetics and product design requirements.

The discipline of Creative Metallurgy involves in depth understanding of several technical areas as well as an understanding of basic aesthetics and product design requirements.

From beginning to end the process of developing a new CM product involves many linked disciplines, some of which are descibed below;

CM requires knowledge of the production of raw metallic materials and an understanding of the economics of those materials in order that the supply chain may be entered at the optimum point. To early, and time and effort is wasted in processing the material, but too late and the aesthetic performance of the material will be too narrow. Pure, elemental, metals are rarely very interesting in aesthetic terms and there is little by way of value that a CM approach can add to them.

A CM practitioner needs to know how metals mix or don’t mix. Atomically close solutions of metals, otherwise known as alloys, are not universal. Some metals don’t mix with others in their molten state and must be mixed in their solid states. The alternative to working with metals in their molten state, Mechanical Alloying, is an energy intense process carried out on the atomic scale, so knowing how best to integrate individual metals into beautiful alloys can bring novel materials to the table with minimum development time and cost.

Similarly there are upcoming opportunities to tune the performance of metals and alloys through the addition of nanomaterials. The area of compound transmetallics is an exciting development that a CM approach will help define.

For a practitioner of CM, knowing how metals will weather or corrode under different environmental conditions can add a fourth dimension to their aesthetics. For example; knowing that a copper roof will turn green after a decade, and over time that verdigree will appear to weep down external walls, will influence both colour choices and drainage of that roof. Control of both the intensity and location of the colour through time can add to the architectural richness of our lives as our built environment changes with us.

Controlling the 3D printing process, from the speed of deposition to the possibility of post-depositional re-heating and quenching will influence both the surface and body of the form being produced, so laser tracking algorithms can be developed to either compensate for or promote certain attributes other than simply the power of the laser and the temperature of the produced melt.

Once a form has been produced with a primary surface treatement, composed of the raw material’s immediate aesthetics, the fourth dimensional aspects of that performance envelope as defined by the form’s intended environment of use, and the mechanism of the build through the interaction of heat, metal and atmosphere, then a suite of post-build treatments may be applied to modulate the primary vectors of aesthetic performance. This may be something as simple as polishing, or as complex as multi-stage acid etching and the addition of enamels.

For the practitioner of CM, removing the built form from the chamber of the printer is like opening the curtains to a stage. Its really just the start !